Rubber cable balancing rope is one of the main elements of multirope lifting system with friction pulleys. It`s reliability and long-term work together with lifring ropes determinate reliabiliity and perfomance work of lifting installation. The main purpose of balancing ropes is to have running weight equal summary running weight of lifting ropes for stabilisation the fliction pulleys moment, friction of lifting machine irrespective of the position of lifting vessels in the trunk of mine. For large multirope lifting installations it is necessary to have balancing ropes with big running weight ( to 30 kg\m).

The highest using indicators and high reliability have rubber cable balancing ropes. Since 2003 ukraininan company "Promkanat" established the production of balancing rubber cable ropes, which are intended for operating in quality balancing in systems mining rise on freight, cager multiple lifting installations and lifts.

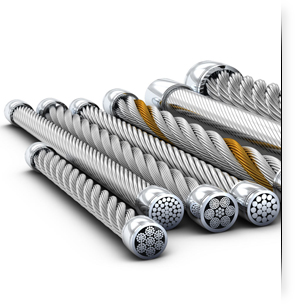

Our company releases the ropes, which consist of rubber metallic core. It`s a parallel located in horizontal plane with certain step, line of steal galvanized ropes, which cured in rubber and external fire-resistant rubber lining.The design of ropes is simple and technological in production. Rubber cable ropes are produced, according to order with requied weight of running meter and length of hinge plates.

The production strengh "Promkanat" is capable to provide rubber cable ropes not only in Ukraine , but especially in countries all over the world. The enterprise saved up a great experiance of operation rubber cable ropes on the various mining lifting installations in Ukraine and CIS countries. This experience confirm about high reliability and efficiency using rubber cable rope in the mining lifting systems.

Geometrical and strengthening parameters of ropes are provided in tables:

| Strength reserve | Limit of using |

| From 5,5 to 7 | 10 years |

| From 7 to 8 | 11 years |

| From 8 to 9 | 12 years |

| From 9 to 10 | 13 years |

| From 10 to 12 | 14 years |

| Over 12 | 15 years |

Steelrope by "Promkanat" produces various types of sizes diameter 0,5 mm - 78,0 mm, that allows to apply successfully a product to any load-lifting mechanisms in a mining industry, metallurgy and building.Process of production includes circle plastic pressing of preparation, the product is a wire in strands with a band contact. High strength of a steel rope is caused by high accuracy of manufacture, and also the used high-quality raw materials.

All list of production conforms to domestic and international standards, such as EN, ISO, GOST, TU. Thanks to removal of internal stresses the rope possesses big flexibility, thus, doesn't lose a path in case of rectification. The product withstands sufficient number of knees therefore breakaways are minimized, and also damages of drums are excluded.

For production the rubber cable ropes our command uses heat-resistant rubber of the Zaporozhye rubber plant. The applied material possesses excellent thermal properties, withstands high and low temperatures without deformation. Thanks to a special chemical composition, rubber is one of the most elastic materials. Protective rubber tabs increase resistance to shock loads and protect construction from longitudinal bursts therefore rezinotrosovy ropes are used for mine rise and in a lift building.